Friday Facts 18: New Makelangelo generators

The Makelangelo plotters software is always getting improvements and today I’d like to share some of the latest with you. As of today the last official release of Makelangelo Software is 7.37. But did you know that exciting work is always going on in the discussion group? Hot new stuff is being added all the time. We’re up to version 7.44. Here’s a list of changes.

- Firmware can now be updated from every platform

- Added image intensity to height converter

- Added Quadtree-like instant filter

- Added Circular mazes

- Added Honeycomb mazes

- Added more Truchet Tiles

- Misc other fixes

Firmware can now be updated from every platform

OSX proved to be quite challenging. But it was worth it if it makes everyone’s life easier going forward. Firmware changes are rare and now they are that much less painful. So now when the code in the brain of the robot is changed you won’t have to jump through a lot of hoops. Instead you can use File > Update firmware and follow the prompts.

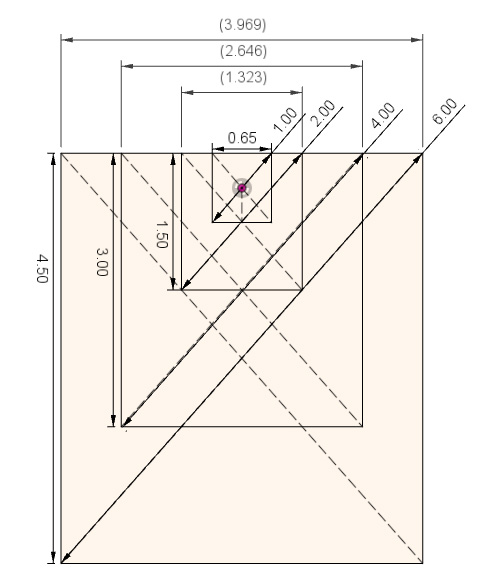

Added image intensity to height converter

The change in height of each line is affected by the intensity of the underlying image. Line spacing and line offset are adjustable from the menus.

Added Quadtree-like instant filter

Contributed by itsMohammedThaier. Starting from the whole picture, divide the rectangle in 4 quadrants. if the chnage in color over a quadrant is too much, split this quadrant and repeat.

Added Circular mazes

What’s not to love? Being randomly generated from a depth-first search, I’m pretty sure there are sometimes two ways to solve each maze.

Added Honeycomb mazes

Would you believe all well-formed mazes are generated the same? The difference is in how the walls are drawn.

Added more Truchet Tiles

Orthogonal, Diagonal, and Curved. You can mix and match them together!

And more!

- Better drawing of counterweights and belts

- Added timestamps to Marlin conversation

- Added more unit tests for unused translations and missing translations

- Internally merged shared code for Vornoi diagrams

- Internally merged shared code for Truchet tiles

- Internally merged shared code for Mazes

Final thoughts

So if any of that seems interesting to you, check it out in the nightly builds.

Thank you to everyone who donated to support the software development. Your donations keep me in beer, and beer keeps me at Ballmer peak.

Discuss this and anything else plotter related on our Discord.