Friday Facts 2: Makelangelo Java GUI

This last week there has been work on Makelangelo software to make it work with the new firmware.

I spent a lot of time using design patterns to decouple classes so they can be independently tested. Usually this means an Observer pattern common in Java: a visible Panel on the screen has a list of registered Listeners and when something interesting happens in the Panel it calls notifyListeners(interestingEvent). This way Panel can be run and tested without needing any specific Listener.

I’d like to change up the code for a MakelangeloRobot to be decoupled from the NetworkSession – the source of data from the real machine. Then data could come from, say, a piece of code reading from a file. That way the state of the machine could be recorded and played back for testing things like “is the machine connecting to you a Makelangelo 5, a 3, a 2, or something else?”

I’m also plagued by ideas about how a Turtle path is used by a MakelangeloRobot. Turtle is a class that contains TurtleMoves, which describe the movement of the pen over the paper. One Turtle per color! Based on the old Commdore 64 turtle, one of the first procedural drawing programs I used as a kid.

Many classes in the Makelangelo app read and manipulate the history of TurtleMoves in a Turtle.

Drawing speed vs quality testing

In a cartesian plotter the velocity, acceleration, and jerk have the same effect everywhere across the work area. Testing such a machine to find ideal speeds is not onerous. I would draw a grid of squares and on the x axis each square would have more velocity while on the y axis each square would have greater acceleration. In this way the sweet spot is easy enough to find.

In a polargraph plotter the challenge is much greater. What works at the top doesn’t work at the bottom, what works in the center might not work on the sides. Simply drawing a set of squares isn’t enough! Long story short I need your help to find the sweetest of sweet spots. Together we can do it. Right? Right??

Spiral improvements

…and that’s all I have to say about that.

Final thoughts

These changes can be downloaded from the Makelangelo project on Github.

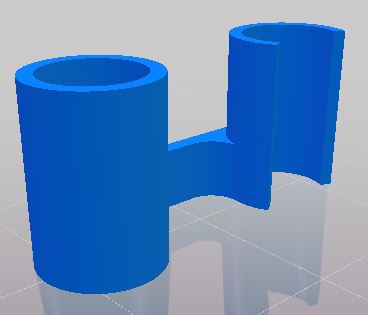

Did you know you can add bars to your timing belt? I didn’t.

Join our Discord to talk more about this post.