Painting a Program (instead of writing)

Flow-based programming is a way of writing programs by drawing pictures of graphs. It’s a very intuitive and friendly way of working. Today I’d like to talk about my adventures exploring this space. I hope that you’ve had similar ideas and would like to join me on this journey.

If you’ve learned to code a little bit, you’re probably familiar with code that looks like this, a method that adds two numbers together:

class Math {

/**

* Returns a+b

* @returns a+b

*/

double add(double a, double b) {

return a+b;

}

}If you play a lot of video games you might have seen designs like this assembler combining two inputs to produce an output in Factorio:

And people born after 2000 are probably familiar with the Scratch programming language from MIT:

I contend that there is a level of abstraction where these are all the same thing. There is a magic box that does a job, some connection to inputs, some connection where to send the results, and visual indicators showing the state of the various elements. In Flow-Based Programming (FBP), Packages of data flow through Nodes. You may have also seen similar models in Unity, Blender, Nuke, NodeRed, and other editing programs. The idea has been kicking around since the 1960s.

Philosophically, I feel that a good use of a maker’s time is to make making easier. The benefits compound! One of the ways FBP makes programming easier is that there are no syntax errors, only logical errors. I can’t forget a pair of braces or a semi-colon. Also values are visible all the time, so no digging into the debugger to find the element I want… the list goes on. Strangely, we still write code as long form text in drab color documents with weird ideas like ‘linking’ and ‘package management’ that should have died in the Cambrian era. Point being I’m highly motivated to use a FBP system.

The system has to be like all modern editors: there has to be a way to extend or plug in or mod new features. It must be easy for everyone to extend in a collaborative way – not just jailed to Unity or Blender, but some where all nodes of all types thrive together. It’s got to be as beautiful and intuitive (and fun) as Factorio. To this end I started an editor called Donatello.

I built a simple Graph that has Nodes linked through their ReceivingDock and ShippingDock by Connections. All data in the system is stored in the Docks. When a ShippingDock is changed it is flagged at dirty. After all nodes are processed the Graph looks for dirty ShippingDocks and copies their values to connected ReceivingDocks, regardless of whatever may be there. When a ReceivingDock is dirty it causes the Node to run on the next cycle. Dirty Docks are marked with red text. After a few days it started to look not awful:

To repeat: Graphs have Connections between Nodes. Nodes have AbstractDocks, some of which are ShippingDocks and some are ReceivingDocks. When a node runs, it might poke the ShippingDock. AbstractDocks might also have one ConnectionPoint each that make it easier to add and remove Connections.

When you want to make a new Node, you have to pick a name, declare the Docks, and write the update() method to read the inputs, do a thing, and probably poke an output.

Part of the motivation comes from making line art for plotter robots like Makelangelo 5. Having written several picture-to-art projects I started to notice similarities. I thought “Wouldn’t it be great if these similar bits were LEGO blocks and anyone could play with them?”

So far I had

- A core NodeGraphCore library defining Graph/Node/Dock/Connection and a Service that plugins can use to advertise their Nodes.

- A GUI built using NodeGraphCore called Donatello. It uses Java ServiceLoader to find valid plugins and load the Nodes.

- A set of Nodes in Makelangelo-software to give me access to all the line art manipulation tools. I put Makelangelo-software in the ~/Donatello/extensions/ folder and then Donatello can do stuff with lines and art.

I put them all together to make some art and test the practical limits of big graphs. Note in the video (3) I am tweaking the program while it is running, tho I could pause it at any time.

What worked

Making new nodes is so easy, as is registering them with a NodeFactory so they show up in the GUI. Using the mouse to move items around, draw and erase connections, and alter behavior was also very intuitive. It was easy to save graphs, load graphs, and step through the program. I have built unit tests without visuals. I can copy/paste/delete/edit nodes and their connections; I can select two nodes far apart and run a tool that selects everything between them in the shortest down-stream path. Undo/Redo work great. I can graph a group of Nodes and Fold them down to a single Node. Put another way, a Node might represent an entire Graph. Folded Nodes can be Unfolded and should have the ability to be saved to a separate file, but it hasn’t been a priority.

What needs work

My first way of drawing connections was straight lines. The second implementation of connections uses Bezier curves. It’s okay…? but now I dream of a third way with right angle lines like I’m used to seeing in a circuit diagram or Factorio.

Also like both circuits and Factorio it would be great if I could rotate Nodes for more intuitive graph layouts.

There’s little visual indication of what connection point can legally attach to another connection point. At least there is some checking! In circuits and Factorio you can connect anything to anything and no one will stop you. Will it run? No. but it also won’t complain, either.

I cannot yet easily make blueprints/templates of popular design patterns as in fig 5. I bet as program grow a lot of patterns will emerge and it would be great to have those ready-to-go.

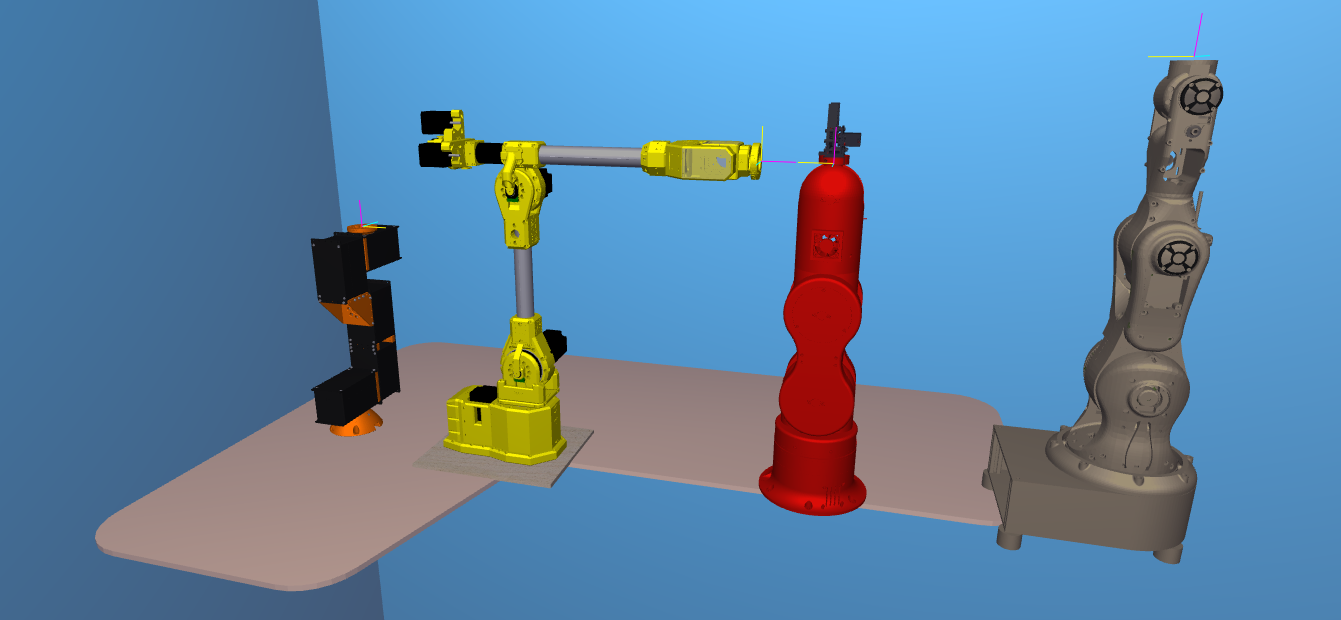

There’s no reason Nodes need to be drawn in 2D. They could be done in 3D just as easily. This is neither good nor bad and I’m sure there’s interesting tradeoffs. I’m not sure I’d want to work with a VR helmet on 8h a day.

Updates to NodeGraphCore mean Makelangelo-software HAS to be rebuilt or the provided Nodes will not load in updated Donatello. Put another way, the version of all three has to match all the time. This is kinda sucky but there’s more! When a plug-in is out of date Java does not give a clear warning – it silently refuses to load and the user is left wondering what went wrong.

What doesn’t work

In classical FBP connections are more like the Factorio conveyor belts: packets of data queue on the connection until the FBP Node (assembling machine) is ready to process them. The Nodes don’t hold on to anything, ever. Resetting the program is as easy as cleaning out all the connections. This is hard in Donatello because there is no distinction between a Node’s current value and its default value. I get around it by saving the state of the graph in the starting state and ONLY the starting state. Yes, I have saved the graph in the wrong state and had to clean it up.

In Donatello nodes contain all data and immediately transmit the results down-stream when they finish a calculation. Also once any input to a node has changed that node will run on the next cycle. This was easy to implement but it has drawbacks later. In a big graph some parts run faster than others. So if a group of nodes A runs twice as fast as some other group B then Add might run A1+0, A1+B1, A2+B1, A2+B2, and so on. You can see it below (8) when TransformTurtle and AddTurtle create unintended noise in the results.

Partial solutions

If the system is set up to run like Factorio or FBP then there has to be one input on each Connection before the TransformTurtle will run. Another way would be an activation trigger – most inputs are optional and nothing runs until data arrives on the trigger input.

I’ve tried twice now to rebuild the Nodes and Connections to work more like classic FBP. There are no more isDirty flags, which means every node has its own “should I run now” test at the start of update() and every Node has to be called every step. This lets me have activation triggers.

The real problem starts when I want to initialize the graph. I need a way to put at least a number or a string of text into Connections so that they flow into the system and make everything run. I can hard-code that kind of thing easily but how do I put it in the GUI? It can’t be a Node because Nodes don’t hold data any more! It’s some kind of new class or interface … maybe Emitter or Entrance or Source. In the model above (7) I had nodes called LoadString and LoadNumber that served well for setting an initial value.

Do all Loaders become ReceivingDock and all… Unloaders? become ShippingDock when Nodes are Folded? Will there be Loaders that should not become ReceivingDock – internal constants?

If a single Loader is supposed to deliver to many Nodes, what then? I’m not going to make many identical Loaders! But I also run into problems when a single Loader is connected to many ReceivingDocks. Data types in Java cannot be cloned (copied) easily. Data types can’t be serialized easy, either. (another way to copy – save and load it into a second instance.) One workaround is to put the same instance of Packet into every Connection. As long as the Nodes treat the Packet as read-only then everything will work…

I feel inspired by Simon Lague’s Digital Logic Sim to put a fence around the entire Graph. The fence is the Node that contains this Graph. Only Loaders and Unloaders that touch the fence are exposed when Folded.

Final thoughts

I’m far from done thinking about this and I’d love to hear your ideas and see your solutions. Find me on Discord and let’s talk about it.