Zippy, a DIY SMT PNP (IFKWIM)

Surface Mount Technology (SMT) are the tiny components found on modern PCBs. They’ve grown so small to build a board by hand you need a microscope and the steady hands of a surgeon… or you build yourself a CNC machine with a vacuum on the end that can pick-and-place (PNP) a board for you. I love automation so I think you know where my vote goes.

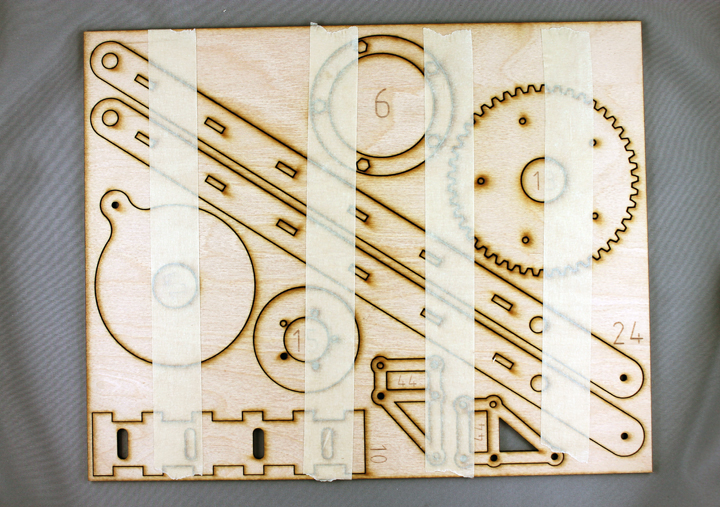

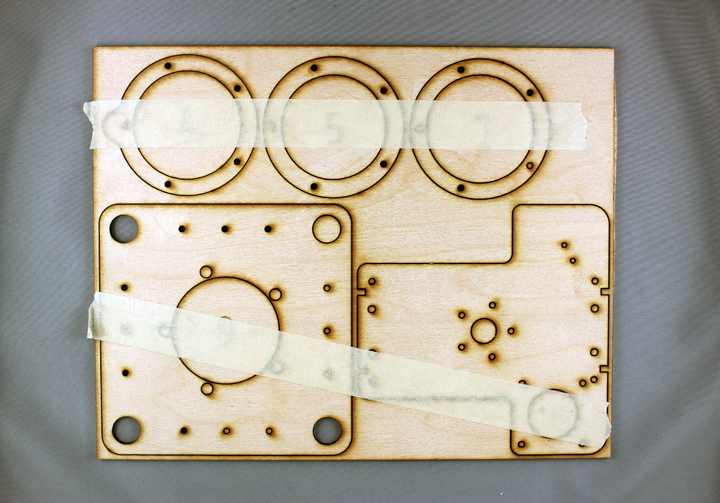

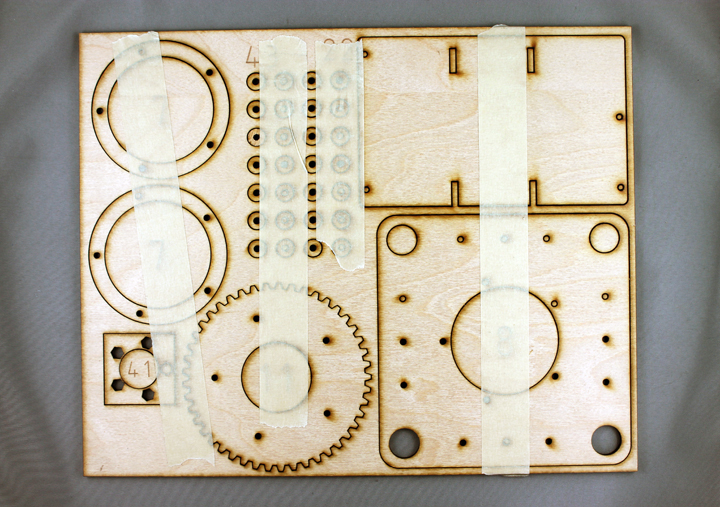

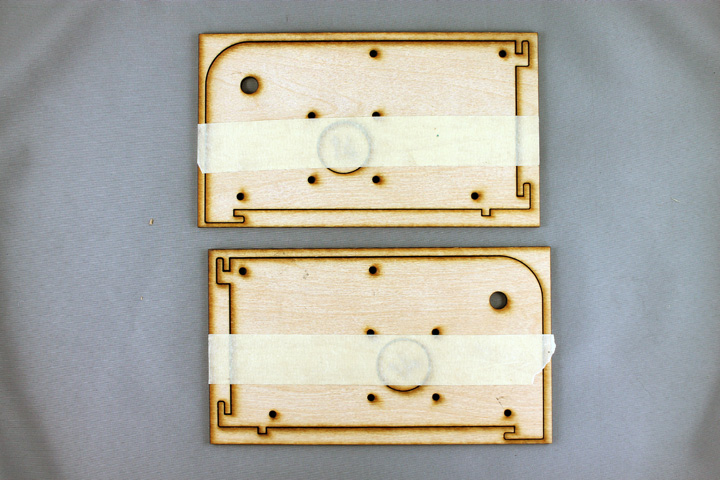

Richard says he runs 20-30 boards a week on it with 1206 parts. The work areas is ~2×4 feet on a 4×6 foot table, most of which is used for having many rolls of components available. The feeders are his own open hardware design designed in OpenSCAD. (mad respect, yo.) It’s a RAMPS/Mega combination running OpenPNP. I wonder if GcodeCNCDemo would help?

I was having people do manual pick and place before. The error level was fairly high. Even though Zippy needs an operator, and does occasionally drop a part, he *never* puts them on in the wrong spot or backwards.

My favorite part is the camera feedback for picking and nozzle calibration. I’ve never done any camera visualization stuff, so this to me is some dark magic right here.